When Holly McQuillan began her PhD almost 5 years ago, she knew very little about the process of weaving or its potential to transform her research practice, which was primarily form-focused in the context of zero waste fashion design and pattern cutting. However, her experience at the Department of Design in the Swedish School of Textiles provided access to exciting technology and skillful colleagues, and combined with her inherent curiosity to lead to a body of research that operates at the boundary between weave thinking and form thinking, helping to grow the emerging field of textile-form (or 3D) weaving.

Holly came to weaving through her experience consulting with industry and researching zero waste design practices and pattern cutting. Like weaving, zero waste garment design is inherently an ancient practice that values textiles first and foremost. In contrast the fashion industry values speed and cost first. As McQuillan discovered during one of her PhD case studies, the industry would rather waste 4km of virgin textiles (on a single style and size for a season!), than add a single seam. In response, Holly’s research began to explore alternative systems of garment and form creation, coming to focus on textile-form weaving, which, like 3D (seamless and fully fashioned) knitting, enables the simultaneous and on-demand creation of textile and form.

The majority of 3D woven garments have been developed by textile designers, so Holly was interested to explore the potential of applying a zero waste form-making lens to the design of weave-able 3D forms. Beginning with simple t-shirt forms (one shown below), the experiments in McQuillan’s PhD, “Zero Waste Systems Thinking: Multimorphic Textile-formsâ€, progressively build a foundation of the textile-form thinking skills needed to construct these complex topologies.

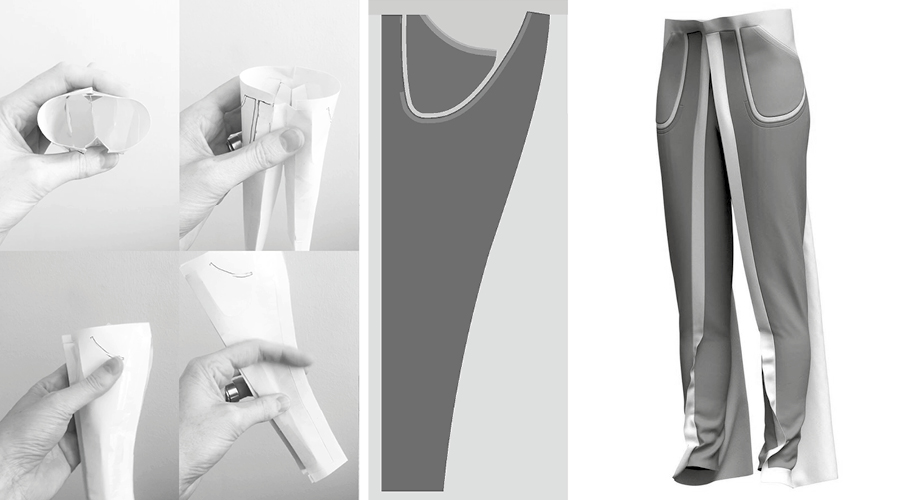

The garments shown here are woven almost fully complete on digital jacquard looms and are designed to be as close to zero waste as possible. In the Trouser example shown below, McQuillan developed a 4 layer textile-form pattern that can be graded (sized), nested, and woven so that only a zipper need be inserted for the trouser form to be realized – details are embedded in the weave itself, such as pockets that utilize the space created by the rise of the trouser. A subsequent collaboration with Dutch weaver Milou Voorwinden has developed the trouser to include surface patterns and recycled denim yarn to create a truly circular outcome.

In Experiment 0 – a collaborative project with fashion design PhD student Karin Peterson, and textile design PhD students Riikka Talman and Kathryn Walters, – McQuillan developed a binding that enables 3D form to be expanded from the alternating interlacement of weft or warp floats. Experiment 0 sought to find new ground at the intersection of the skills and interests of the four collaborators. It uses shape-changing materials to develop a new form design and production approach that embraces time and change as a design variable. Through this approach one material and one garment can have many expressions over many lifetimes – a necessity in developing the circular design systems of the future. This perspective was developed further in Peterson, Walters and McQuillan’s work for the film Planet City (2020).

Integrating more of the garment supply chain is important for the development of new sustainable production systems. Integrating yarn spinning into her textile-form weaving, Holly has collaborated with Berlin-based Studio Hilo on the H||H System (shown below) developed during the 3rd Call of the EU funded WORTH Project. Studio Hilo have developed software and hardware that enables yarn to be spun with variable thickness along a continuous length. In the H||H System the yarn is engineered to compensate for changes in warp and/or weft density resulting from combining weave structures with different numbers of layers into one woven textile – a phenomena Holly calls “fractional densityâ€.

Integrating more of the garment supply chain is important for the development of new sustainable production systems. Integrating yarn spinning into her textile-form weaving, Holly has collaborated with Berlin-based Studio Hilo on the H||H System (shown below) developed during the 3rd Call of the EU funded WORTH Project. Studio Hilo have developed software and hardware that enables yarn to be spun with variable thickness along a continuous length. In the H||H System the yarn is engineered to compensate for changes in warp and/or weft density resulting from combining weave structures with different numbers of layers into one woven textile – a phenomena Holly calls “fractional densityâ€.

The further into this research Holly delves, the more integrated form-thinking and textile-thinking have become. Weave structures and materials work in harmony with form construction techniques to produce outcomes that are often unlike many others – and could not be made using conventional garment construction methods such as cut and sew. Despite developing her understanding of weave-thinking, Holly still works extensively with weave specialists such as Kathryn Walters and Milou Voorwinden to further develop her ideas. She sees her work not as replicating the skills of the weaver, and instead seeks to forge a new space between textile and form design that requires new ‘multimorphic’ skills.

Holly’s research argues that the designers of the future need to be multimorphic thinkers – able to traverse multiple scales and perspectives to solve the complex problems of our industry. She says they must be able to collaborate and communicate with more parts of the industry and consider how the microscopic details of their weave structure and material use can impact on the macroscopic planetary scale. This is the essence of the multimorphic and holistic thinking that Holly explores through weaving in her research.

Holly McQuillan was recently appointed Assistant Professor of Materializing Futures at TU Delft in the Netherlands, and continues her collaborations through the design research studio Critical Textile Topologies.

With much thanks to Dr. Holly McQuillan for her text and images:

Image Captions

Image 1: Feldspar Dress for Planet City (2020): by Holly McQuillan, Karin Peterson and Kathryn Walters.

Planet City (2020): Director and Production Designer Liam Young with Costume Director/Producer Ane Crabtree, Still photography by Driely S. Mask artist: Aneesa Shami.

Image 2: Experiment 5: T-shirt Iteration Two) on loom (2018), by Holly McQuillan. Experiment 5: T-shirt Iteration Two) on body (2018), Photography by Thomas McQuillan.

Image 3: Experiment 11: Trouser Iteration One, Paper model, digital ‘artwork’ and 3D digital render in CLO3D (2019), by Holly McQuillan. Photography by Holly McQuillan.

Image 4: Experiment 0, 1:1 mould, shrunk on mould and shrunk in dryer (2020), by Holly McQuillan, Karin Peterson, Riikka Talman and Kathryn Walters. Photography by Amanda Johansson.

Image 5: Experiment 0, shrunk on mould, detail of expanding binding (2020), by Holly McQuillan, Karin Peterson, Riikka Talman and Kathryn Walters. Photography by Amanda Johansson.

Image 5: H||H System dress, detail of expanding binding, uncut textile (2021), by Holly McQuillan and Studio Hilo. Photography by Thomas McQuillan.

{ Comments are closed! }