Humphries Weaving are one of three esteemed companies weaving at the Historic Sudbury Silk Mills, designing and weaving bespoke fabrics for artists, interiors designers, architects, ecclesiastical projects, historic houses and many other iconic institutions.

Humphries Weaving are one of three esteemed companies weaving at the Historic Sudbury Silk Mills, designing and weaving bespoke fabrics for artists, interiors designers, architects, ecclesiastical projects, historic houses and many other iconic institutions.

They collaborate closely with their clients, starting with initial design; all the way through to the finished fabric. The mill itself is fully equipped to deliver these requirements with yarn dyeing, warping, weaving and finishing also undertaken onsite in Sudbury, Suffolk.

Humphries Weaving are excited to be able to offer an opening for someone to join their team as an account manager.

What you will bring;

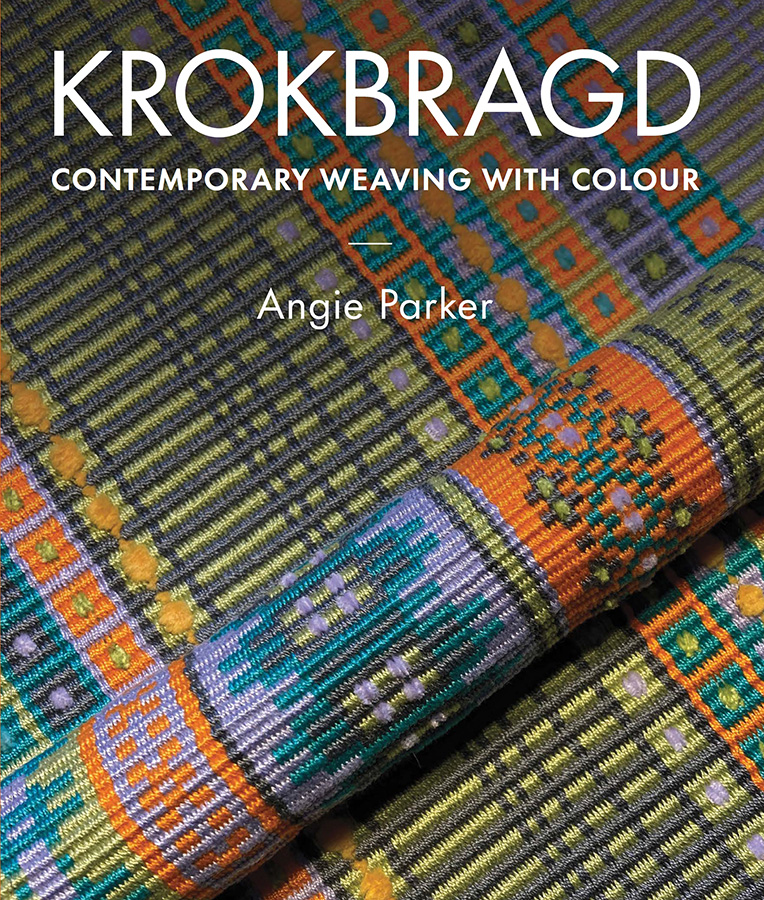

You are inspired by fabrics, colour, texture and decorative arts and enjoy talking about this with like minded people at every opportunity.

- You have a passion for heritage; from buildings to craft, you love to promote skills and shine lights on hidden areas.

- You are highly curious about people, projects and concepts; you enjoy researching, uncovering details and presenting solutions and technical information in an easy-to-understand way.

- You have a desire to be connected to bespoke manufacturing and can’t wait to be hands on developing fabrics at the mill through the skill of design and innovation.

- You bring energy to opportunities and thrive on each day being different.

- Above all you love working as part of a dynamic team, providing positive contributions, working towards shared goals, actively supporting each other and sharing project success.