Weaving on the new TC2 – Digital Weaving Norway

Stacey Harvey- Brown had the good fortune to be in Norway, at the factory of Tronrud Engineering where the TC1 and TC2 computer hand-jacquard looms are manufactured. She got to work within the factory environment where the staff were friendly, extremely knowledgeable and listened to the user, creating or adapting equipment directly from weaver feedback.

Vibeke Vestby, the dedicated and inspiring weaver and creator of the TC1 and now the TC2, invited Stacey over to test weave on the TC2 with non-traditional weave techniques to see how well the loom could cope. She reports that the loom coped very well. One or two suggestions were acted on immediately, and modifications were made which improved the weaving experience. The TC2 is a faster loom than its predecessor, which delighted her, as that was probably her main criticism of the TC1. She had found that the TC1 wouldn’t allow getting into a comfortable weaving rhythm when only using one shuttle, and this has been addressed with the TC2. Stacey is a fast weaver with one shuttle, and although the TC2 isn’t quite as fast as she is, she was still able to get into a good weaving rhythm. When you use more than one shuttle, the speed certainly is not an issue.

The action of the loom is smooth. The heddles now lift inside a frame – not dissimilar to traditional jacquard – and there are fewer ends that misbehave. She had 2 that refused to co-operate out of 2640. Stacey has more than that on my baby jacquard sample looms from the 1880s which are completely manual. The curing of that kind of problem is also much easier, and hopes to have more time to investigate this on another visit.

The actual hardware on the TC2 is much less frantic than the TC1. Instead of cables everywhere, there are simple modules with vacuum hoses. The bulk of the electronics are in the side frame so reducing the amount of trailing cables. The design of the frame is cleaner, less industrial and somehow more ‘friendly’.

Continue reading →

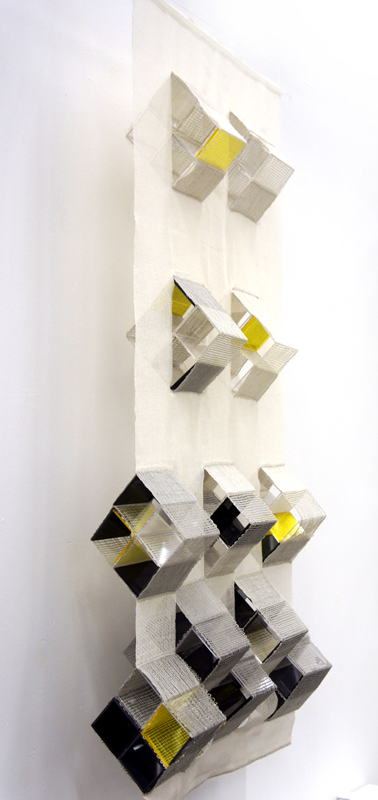

Using unusual materials to create three-dimensional woven forms, Jane Harper has pushed the possibilities of what can be achieved within loom based woven art.

Using unusual materials to create three-dimensional woven forms, Jane Harper has pushed the possibilities of what can be achieved within loom based woven art.